News

Research project discovers ways to convert forest industry’s carbon dioxide emissions into raw material for plastics

VTT Technical research centre of Finland and LUT University have completed a three-year research project on carbon capture and utilisation. The project investigated different technologies for producing renewable plastic raw materials from carbon dioxide and green hydrogen. Renewable energy, hydrogen economy and forest industry’s biogenic carbon dioxide emissions present significant opportunities for new sustainable industries.

Andritz launches R&D program to double value from wood without more harvesting

Andritz is launching a comprehensive research and development program called BioCircleToZero, which aims to double the value derived from wood without harvesting more trees. Business Finland, the government’s agency for trade and investment promotion, has granted Andritz 10 million euros in funding for the BioCircleToZero program. An additional 20 million euros will be provided by Business Finland to partners contributing to the program.

Valmet delivers complete IQ Quality Management System package to pressure-sensitive laminate producer in North America

Valmet has received an order for a complete Valmet IQ Quality Management System package from one of North America’s largest pressure-sensitive laminate producers. It will be delivered to the customer’s Midwest facility and include Valmet IQ Moisturizers for moisture and curl control, Valmet IQ Silicone measurement, Valmet IQ Reflective Spectrometer measurement for adhesive, two Valmet IQ Single Sided Scanner S units, and closed-loop moisture MD/CD control and MD Silicone control. The order is included in Valmet’s orders received for the first quarter of 2025. The value of the order will not be disclosed. The delivery is scheduled for August 2025.

EraCup Natural by Lecta obtains DIN CERTCO industrial compostability certification

Lecta has achieved DIN CERTCO industrial compostability certification for its EraCup Natural paperboard, an innovative product for food service applications. Why is this certification important? It ensures that compostability claims are scientifically validated and that items are accepted in industrial composting facilities, unlike “biodegradable” products that may not fully degrade.

Intergraf and partners provide clarity on geolocation data in EU Deforestation Regulation

A coalition of industry associations, including Cepi, EMMA, ENPA, EPC, FEP, Intergraf, and News Media Europe, has released a joint statement to address misconceptions surrounding the role of geolocation data in compliance with the EU Deforestation Regulation (EUDR). This statement aims to support printing companies in their EUDR discussions with customers, clarifying that geolocation data are not required in EU value chains for compliance.

Voith sets for itself scientifically based climate targets

The Voith Group has set for itself scientifically based climate targets. Accordingly, the company is committed to reducing the greenhouse gas (GHG) emissions of its own sites (Scope 1 and Scope 2 emissions) by 50.4% by fiscal year 2031/32 compared to the baseline year 2021/22. In addition, Voith aims to reduce GHG emissions from the use of its products (Scope 3) by 30% over the same period.

Klopman and TDV Industries: A tool with EPD / Environdec certification for fabrics

Klopman and TDV Industries, a France-based company specializing in textiles for technical and military clothing, proudly announce the completion of an innovative project for the creation of an advanced tool to calculate the Life Cycle Assessment of their fabrics. The tool has obtained the prestigious and well-recognized EPD (Environmental Product Declaration) certification from Environdec.

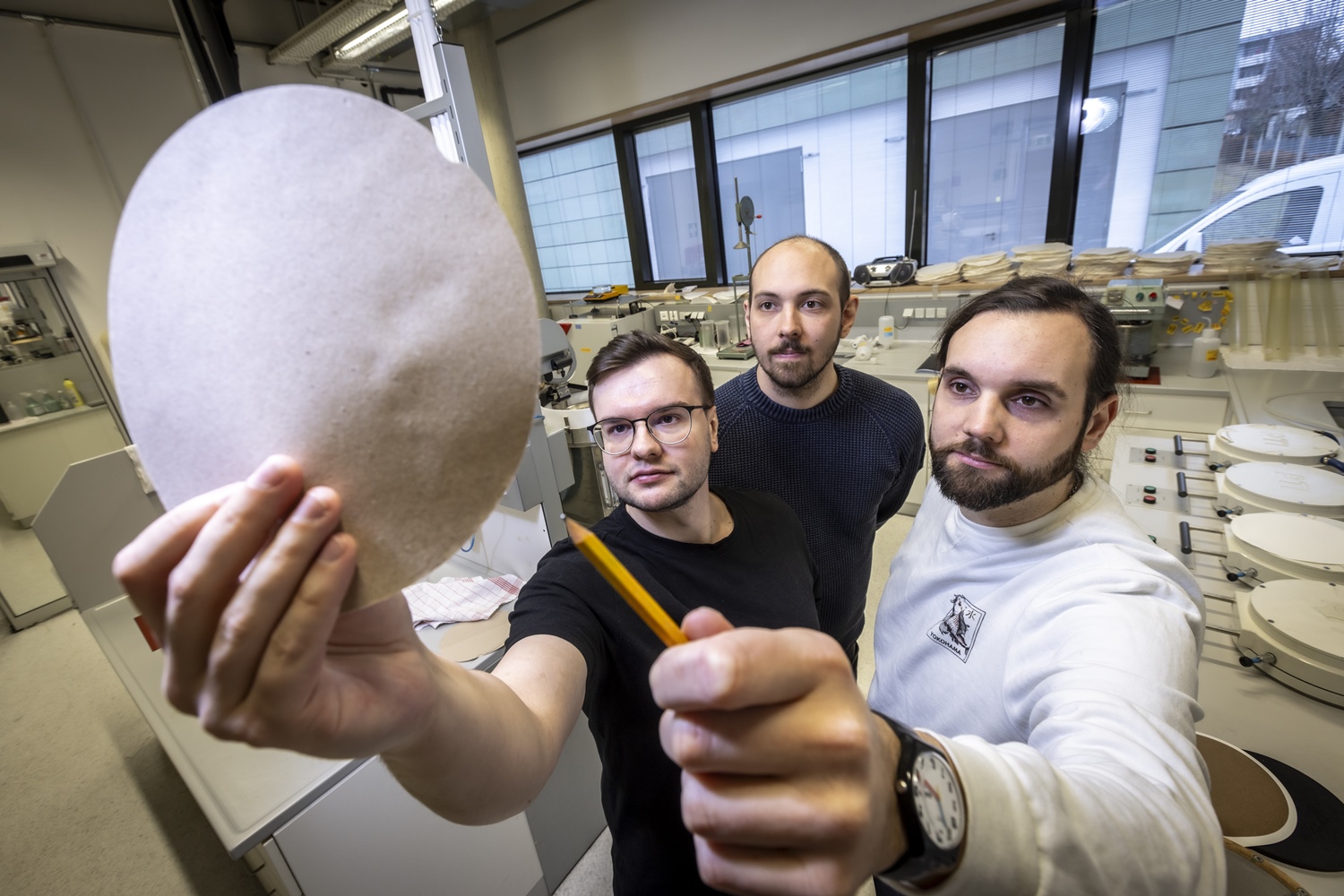

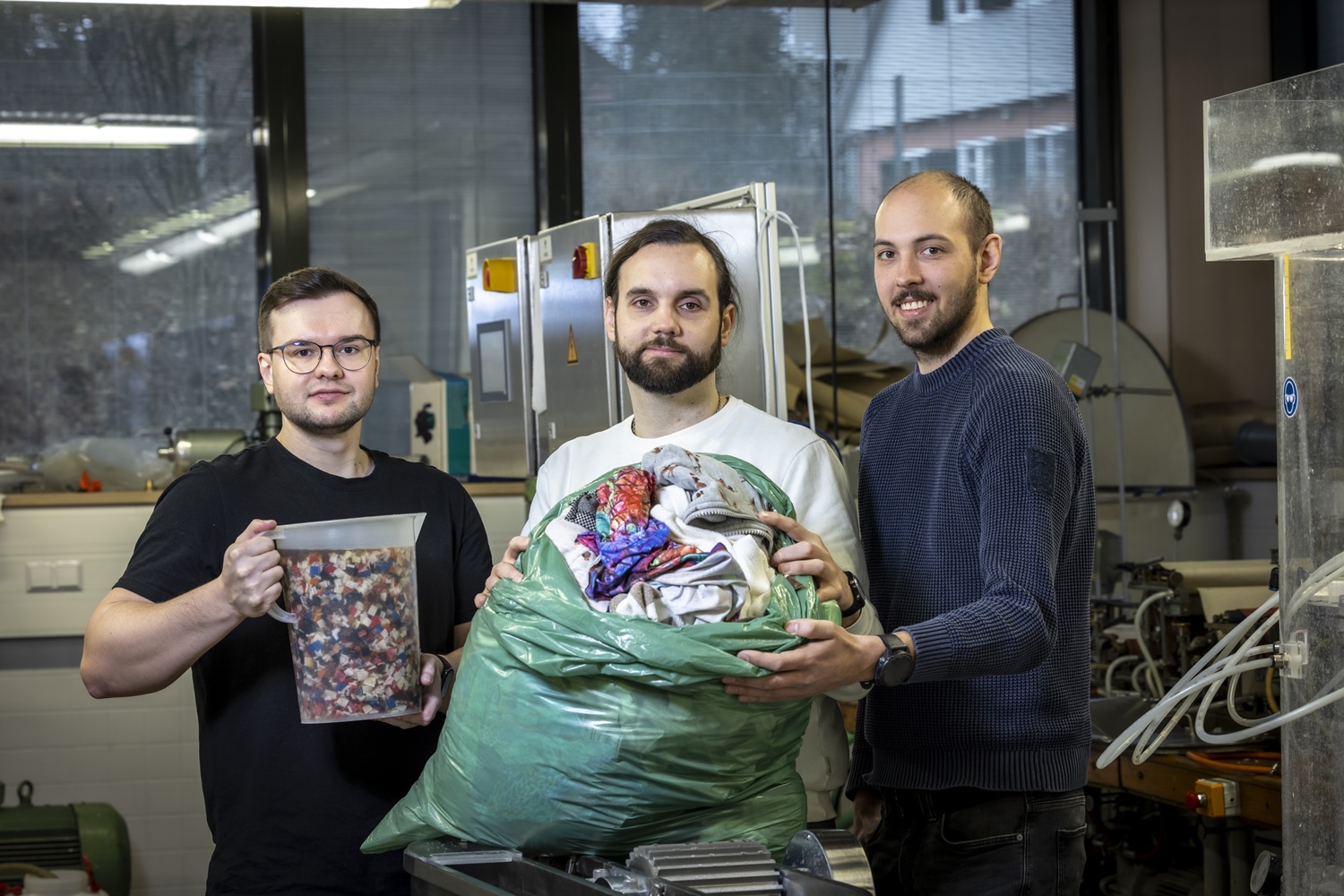

Researchers at TU Graz turn textile waste into paper

Until now, old clothes have mainly been incinerated. Using adapted processes from paper production, it is possible to recover the cellulose fibres from used clothing and use them to produce cardboard and other packaging materials. In Austria alone, around 220,000 tonnes of textile waste are produced every year, of which almost 80 per cent is incinerated. As a result, valuable raw materials are irretrievably lost. A team led by Thomas Harter from the Institute of Bioproducts and Paper Technology has come up with a sustainable solution to this problem. The researchers have developed a process to recover the fibres from cotton-based used textiles and use them to produce paper for packaging materials. Compared to conventional recycled paper, the paper with textile fibre content proves to be significantly stronger.

Andritz airlay line for nonwovens production from recycled glass wool starts up at Revibat, France

International technology group Andritz supplied and recently commissioned a state-of-the-art neXline airlay system for Revibat, France. This innovative line, inaugurated at the beginning of February, enables the production of building insulation panels from glass wool waste that would otherwise be sent to landfills. With the new Andritz line, Revibat can now transform complex waste collected in the Paris region into valuable products. The patented process addresses two major challenges: giving a second life to insulation glass wool waste and reducing the carbon footprint across the entire production chain.

Klopman commits to 100% renewable energy and further reduces emissions with new innovations

Klopman, a global player in the production of high-performance fabrics for workwear, protectivewear, and casual apparel, is proud to announce a major milestone in its commitment to sustainability. From today, 100% of the energy used in all Klopman production processes will be derived exclusively from hydroelectric sources. The company is carrying out LCA – Lyfecycle Assessments on all its fabrics and the introduction of this major implementation will bring a benefit between 6 and 8% in the products Carbon Footprint (depending on the fabric).

Valmet to retrofit automation at KSS Energia’s Verla 2 hydropower plant in Finland

Valmet will modernize the automation system at KSS Energia’s Verla 2 hydropower plant in Kouvola, Finland. The Valmet DNA Hydro Turbine Automation will replace an obsolete third-party system on the site. The new automation system plays a crucial role in improving the operational reliability of the hydropower plant. The order was included in Valmet’s orders received of the fourth quarter 2024. The value of the order will not be disclosed. The delivery will be taken over by the customer in December 2025.

Södra delivers CLT to Gothenburg Grand Central

The construction of Gothenburg Grand Central has started, a new station building in a completely new district. Together with Hybridge, Södra is delivering 9,100 square meters of cross-laminated timber (CLT) for the building's frame. Gothenburg's new station building is a project with a clear focus on sustainability and a minimized climate footprint. The majority of the building's structure is made of wood, which is combined with recycled bricks, climate-improved concrete, and recycled steel.